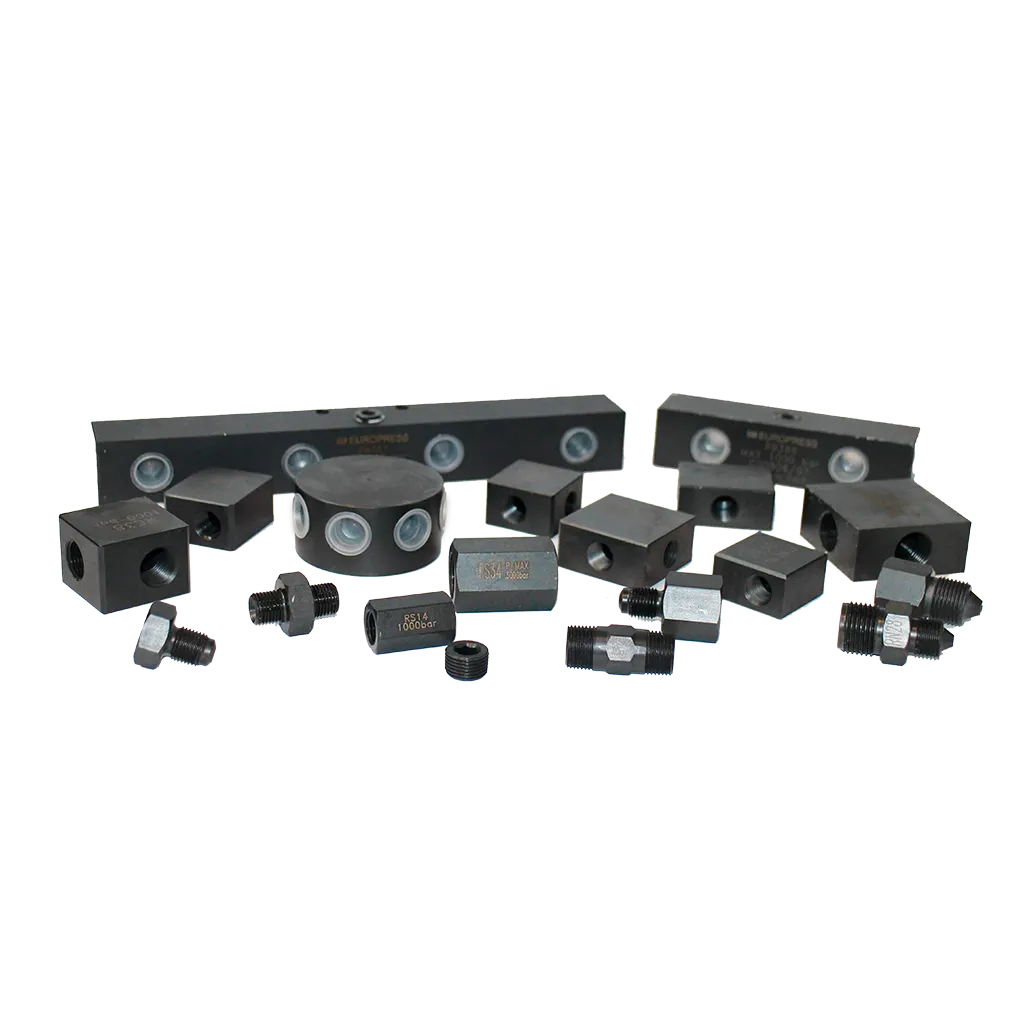

Max working pressure: 1000 – 2000 – 3000 bar

Applications: 3 – 9

The fittings range at 1000 bar guarantees a 4 safety factor if used at 700 bar w.p., and a 2,8 safety factor if used at 1000 bar w.p.

All EUROPRESS products are covered by a one year guarantee against any defects in materials or workmanship. This guarantee does not cover normal wear and tear, improper use or any applications not in compliance with our recommended instructions, or where the equipment is used with unsuitable fluids, modifications and/ or alterations (including those resulting from repair or attempted repair by persons not authorized by EURO PRESS PACK), or damage caused by transportation.

To report any flaw, defect, non conformity, and/or to claim action under this guarantee, the Customer shall inform EURO PRESS PACK in writing within 5 days after receipt of the goods, or in case of hidden defect, within 5 days after such defect has been discovered. Before returning the goods to EURO PRESS PACK for possible remedy under guarantee, the purchaser shall have received EURO PRESS PACK’s authorization . If EURO PRESS PACK is firmly convinced that its own product is defective, EURO PRESS PACK will provide free of charge for repair or replacement. The transport costs to and from EURO PRESS PACK are at the customer’s charge.

If the intervention of EURO PRESS PACK personnel or of our authorized distributors is requested on the site for installation of the replaced items (provided it is ascertained that they are covered by this guarantee) the costs of transfer of such personnel, their travelling hours and travel expenses are at the Customer’s charge, whereas only the actual working hours will be at the charge of EURO PRESS PACK or of its authorized distributor.

THE ABOVE GUARANTEE IS THE ONLY GUARANTEE ACKNOWLEDGED AND RECOGNIZED BY EURO PRESS PACK AND IT REPLACES ANY AND ALL OTHER EXPLICIT OR IMPLICIT GUARANTEES REGARDINGTHEPRODUCTSMANUFACTURED AND MARKETED BY EURO PRESS PACK, AS TO THEIR MARKETABILITY OR SUITABILITY FOR SPECIFIC APPLICATIONS.

IT IS HEREBY EXPRESSLY STATED THAT ANY CHARGES AND/OR LIABILITY OF EURO PRESS PACK ARE EXCLUDED REGARDING:

THIS GUARANTEE WILL NOT BE EFFECTIVE IN CASE OF EVEN PARTIAL DEFAULT IN PAYMENT FOR THE SUPPLIED GOODS, INCLUDING INVOICES FOR TECHNICAL ASSISTANCE SERVICES.

The maximum amount payable by EURO PRESS PACK for damages will at all events be limited to the actually paid purchase price and shall therefore never exceed this price.

I In case of goods lost during transport, please contact the company within 30 days of loss: sales@europresspack.it

QUALITY CERTIFICATION

Euro Press Pack has always been a Company very attentive to quality norms. This means that both the design of our products than their manufacturing are planned considering the Good Manufacturing Practice.All necessary controls are made to grant our customers the highest possible quality standard. In this way the final product is produced and checked according to the defined procedures and this assures that the quality system is efficient, controlled and proved.

QUALITY SYSTEM CERTIFICATE ISO 9001

Certification for design, manufacturing, marketing and repair of high pressure components.

ENVIRONMETAL SYSTEM CERTIFICATE ISO 14001

System certification for design and manufacture, through the various step of cutting, mechanical machining, surface treatments, painting, assembly, testing, packing and dispatch, sales and service of high pressure hydraulic fluid components.

ANSI B30.1

All cylinders comply to the standard laid down by the American National Standards institute (apart from CGS#P#, CGG#P#, and CGR cylinders).

EN 60204-1

The electric parts of the machines are made according the standard of EN 60204-1.

SAE 100R10

The 700 bar hoses exceed this norm.

Direttive CE 2006/42/CE – CE 2006/95/CE – CE 2004/108/CE

All our power packs conform the CE norm on the machine directive, low tension and electromagnetic compatibility.

CE mark.

All EUROPRESS products meet the European safety directives. Except certain systems or utensils which are designed for a specific use and are certified as machineries, all the cylinders, pumps and power packs of generic purpose are accompanied by certificates. The CE certification is responsibility of the construction of the machinery in which all the components are assembled.

Thanks to our speedy deliveries you don’t have the urge to place a huge stock order to assure your customers a good service